MES Implementation and Integration

MES Implementation and Integration

We provide high-quality modern software adapted to your needs. Modular build and plenty of add-ons are ensuring fast implementation and immediate return on investment.

MES Implementation Steps: From Planning to Execution

Our MES implementation process follows a structured approach to ensure seamless integration with your existing systems while maintaining GAMP®5 compliance. With a modular, pharma-focused MES platform, we deliver a fast, scalable, and future-ready solution.

Step 1: Requirements Analysis & System Design

We conduct an in-depth analysis of your pharmaceutical manufacturing processes, existing systems, and business requirements. Based on this assessment, we define the right MES modules to align with your operational goals and regulatory needs.

Step 2: Agile Implementation & Configuration

Using a standardized, agile approach, we implement and configure MES solutions tailored to your production workflow. The system is designed to support digitized production orders, batch tracking, scheduling automation, and more while ensuring regulatory compliance.

Step 3: Machine Connectivity & Data Integration

We enable seamless machine connectivity by integrating with PLCs from Siemens, Allen Bradley, Beckhoff, B&R, and others. Through standard communication protocols such as OPC, MQTT, Modbus, and Ethernet/IP, we ensure real-time data exchange between machines and MES.

For legacy equipment, we deploy Edge IIoT modules with additional sensors to bridge connectivity gaps and unify data across your production line.

Step 4: Validation & Deployment

Once implementation is complete, we conduct a rigorous validation process to ensure data integrity, system reliability, and regulatory compliance. The final deployment phase includes GxP-compliant validation, live system testing, and production rollout across all sites.

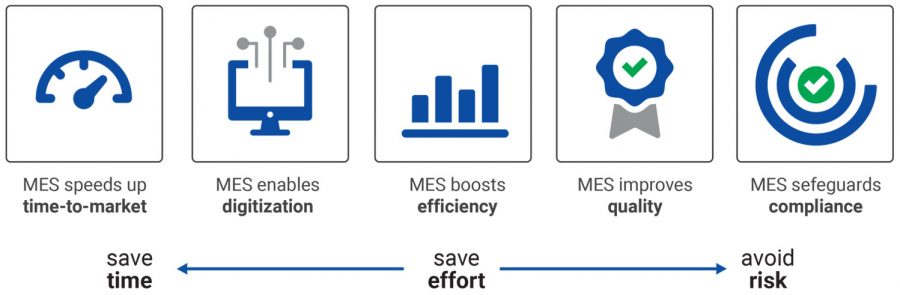

Key Benefits of Vimachem MES Implementation & Integration

Faster Changeovers & Increased Efficiency

Reduce production downtime with optimized workflows and real-time system adjustments that improve resource utilization and overall manufacturing performance.

Full Paperless Manufacturing

Eliminate manual paperwork and switch to a fully digital MES system, ensuring accurate data tracking, improved audit readiness, and seamless compliance with regulatory requirements.

Accurate Scheduling & Production Optimization

Leverage automated scheduling and real-time data synchronization to reduce bottlenecks, improve batch tracking, and ensure on-time production while maintaining flexibility for demand changes.

GAMP®5-Compliant MES Solutions

Ensure regulatory compliance with a validated MES implementation that follows GAMP®5 and GxP guidelines, providing a secure and scalable solution for pharmaceutical manufacturing.

Seamless Integration with Enterprise Systems

Achieve end-to-end data connectivity by integrating MES with ERP, APS, LIMS, and other business-critical systems, ensuring data consistency and improved decision-making across all production levels.

Advanced Equipment Connectivity & Automation

Connect both modern and legacy machines through standard communication protocols (OPC, MQTT, Modbus, Ethernet/IP) and Edge IIoT modules, enabling real-time monitoring, predictive maintenance, and operational visibility.

Scalability for Global Deployments

With 150+ implementations across 25+ countries, our MES platform is built for scalability, allowing manufacturers to expand operations effortlessly while maintaining system stability and performance.

Why Choose Vimachem for MES Implementation & Integration?

At Vimachem, we specialize in fast, efficient, and scalable MES implementation and integration designed specifically for pharmaceutical and biopharmaceutical manufacturing. Our modular MES solutions and plug-and-optimize approach ensure a smooth deployment with an immediate return on investment.

Ready-to-Use & Scalable

Our modern MES software is highly configurable with a modular build and add-ons that allow for fast implementation and long-term scalability.

Pharma-Focused

Our MES solutions come with industry-specific features and modules tailored for pharmaceutical and biopharma manufacturers, ensuring compliance and performance optimization.

Seamless System Integration

We enable end-to-end data connectivity by integrating with ERP, APS, LIMS, and other enterprise systems, ensuring data integrity and efficient knowledge transfer.

No-Code, Highly Configurable Platform

Our IIoT-native platform is fully configurable without coding, allowing you to adapt MES to your unique manufacturing requirements without extensive custom development.

Agile Deployment & Compliance

We follow an agile pharmaceutical project management approach while ensuring compliance with GAMP®5 guidelines, allowing for rapid deployment without compromising on quality or validation requirements.

WORLDWIDE IMPLEMENTATIONS

Implementations

Countries

Customer Satisfaction

From Pilot Phase to Scalable Global Deployment

24/7 CUSTOMER CARE

// We provide global support with SLA which is highly important to critical pharmaceutical and biopharmaceutical manufacturing systems.

Ready to Augment your Shop Floor Operations?

Ready to Augment your Shop Floor Operations?

Get started with real-time manufacturing analytics today.