What is an Electronic Logbook (eLog) & its Importance in Pharma

What is an Electronic Logbook (eLog) & its Importance in Pharma

Today, pharma manufacturing goes a step further into digitization by replacing paper records with electronic logbooks.

Revolutionizing log data management, cloud-based applications enforce integrity, efficiency, and compliance in ways traditional paper logbooks cannot.

What is an Electronic Logbook (eLog)?

An electronic logbook (eLog or e-logbook) is a software solution that documents and manages any data related to manufacturing processes. Things like laboratory operations and equipment calibration events are all automatically recorded in e-logbooks.

In pharma production, electronic logbooks outperform their paper counterparts. Their interconnected build significantly improves data integrity, efficiency, security, and adherence to regulatory standards.

E logbook vs. Paper Logbook in Pharma

In the past, pharma manufacturers used paper logbooks to log activities such as equipment maintenance, area cleaning and sanitization, operator activity, etc.

But, at the same time, they had to deal with paper-born challenges: unnecessary costs, avoidable errors, data loss, and data breaches.

E logbook solutions address these problems in various ways.

They provide key benefits, including:

Improved Data Integrity & Accuracy

With features like time stamps and electronic signatures.

Streamlined Data Management

With built-in tools for data analysis and reporting.

Enhanced Security & Compliance

Using advanced access control and user authentication to fortify data security.

And these are just some of the benefits electronic logbooks offer to pharma and biopharma manufacturers.

Let’s take a closer look.

Why are Electronic Logbooks Important in Pharma?

To be ahead in digital transformation and stay competitive, pharma companies must incorporate robust log reporting systems into their daily operations.

In this environment, digital logbooks are an indispensable tool, streamlining operations while minimizing resource use, energy consumption, and data integrity risks.

Here’s why:

Undisputable Data Accuracy

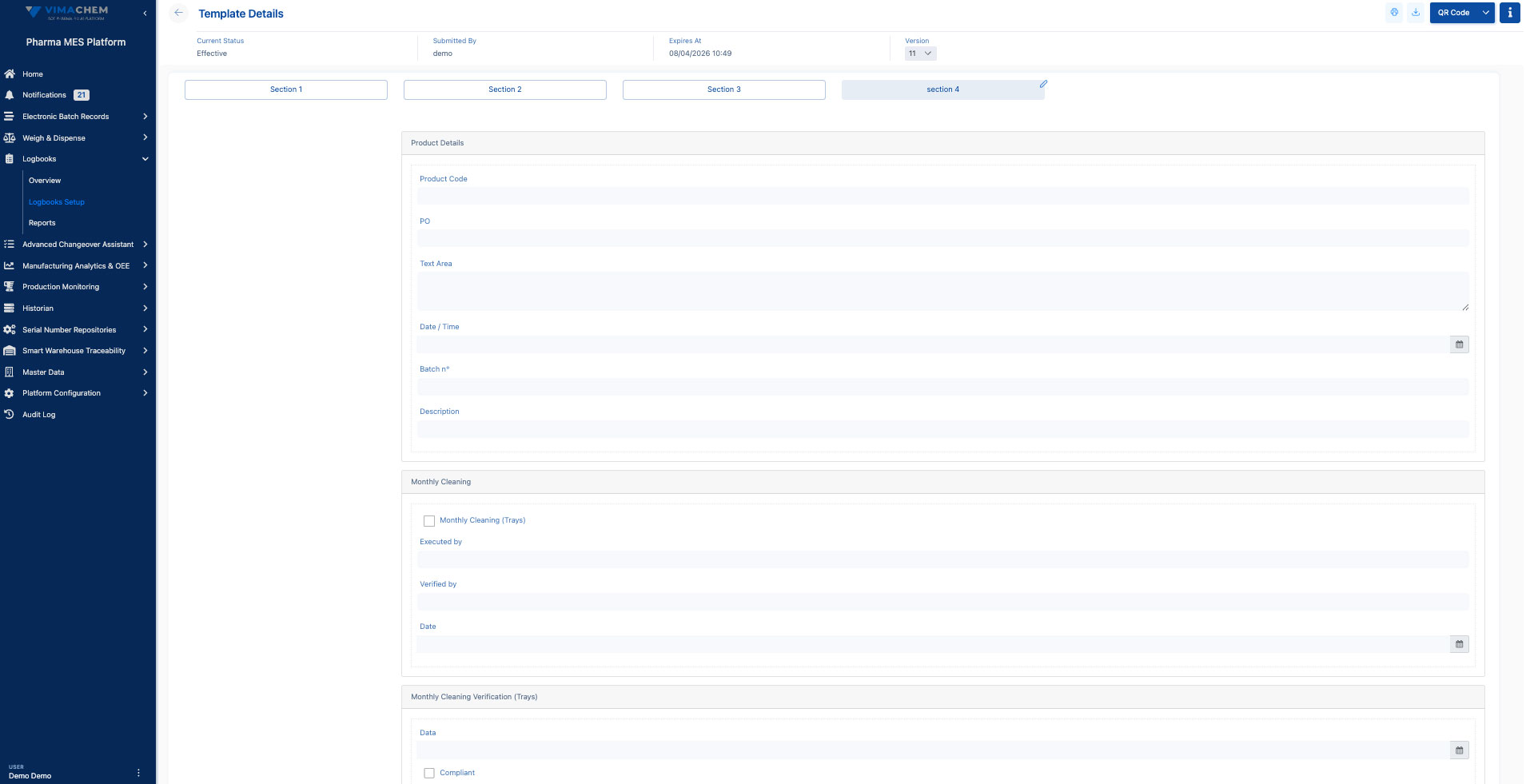

E logbooks eliminate the potential for human error. To illustrate this, let’s look at their user interface, which includes auto-populated fields as well as (customized) mandatory fields.

This feature ensures that record data is always complete before it is submitted into the system and in addition it accelerates data validation checks.

Ensures Near-Zero Risk of Data Loss

E-logbook data is stored on secure servers (with regular back-ups) or in the cloud. So, it’s virtually impossible to lose any data.

24/7 Accessibility

An electronic logbook can be accessed at any time, from any place, and on any device (once you have internet connection).

Authorized staff can track and monitor manufacturing activities 24/7 and quickly respond to any issues that arise.

Smooth Shift Handover

Shift handover, a critical aspect in pharma manufacturing, is far more efficient with eLogbook software.

Incoming shifts can instantly access departing teams’ logbook entries, enabling them to address any issues promptly and efficiently.

Automated Deviation Reporting

Real-time data collection triggers deviation reports when processes exceed specifications. Therefore, issues are identified on the spot and promptly resolved.

Effective Reports & Data Analytics

Complex data is presented in customized visual reports, making it easy to visualize trends and patterns and analyze them to improve products, processes, and market share.

Audit-Ready

A modern eLogbook software maintains comprehensive audit trails, documenting every modification and action associated with the entries while generating automated audit reports.

Compliance-Ready

Electronic logbook software helps pharma manufacturers comply with regulations such as the FDA’s 21 CFR Part 11 and EU EudraLex Volume 4 Annex 11 – both of which define requirements for electronic records, electronic signatures, and data traceability in GMP environments.

Choosing The Right Electronic Logbook Software

With the revenue in the Pharmaceuticals market estimated to reach US$1,207.00bn in 2025 and an annual growth rate (CAGR 2025-2029) of 4.76%, selecting the right eLogbook software is not a task to take lightly.

Some factors to consider include:

Compliance With Regulatory Requirements

The pharmaceutical manufacturing sector is highly regulated. It’s then crucial to choose an eLogbook software that adheres to these regulations. More specifically, your software should:

- Comply with Current Good Manufacturing Practices (cGMP)

- Support electronic signature capture

- Track audit trails

- Fulfill data integrity standards

Additional considerations include:

User-Friendly Interface

A straightforward, easy-to-use interface facilitates data entry, search, and retrieval.

Another important aspect is the ability to add customizable fields, which allows you to capture data points specific to your pharmaceutical company.

Integration With Other Systems

To maximize efficiency, your eLogbook software must also seamlessly integrate with or work within your other systems, such as:

- Manufacturing Execution Systems (MES).

- Enterprise Resource Planning (ERP) systems.

- Electronic Batch Records (EBR) software.

This will enable real-time data sharing and minimize data errors and inconsistencies.

Scalability & Flexibility

Your electronic logbook solution must be scalable and grow with your business.

It needs to handle increasing numbers of users, equipment, and data points and incorporate new processes as your company expands.

And, it should be flexible enough to adjust to new federal regulations.

Security & Data Privacy

Choose a software that incorporates strong security measures to safeguard your data’s confidentiality and integrity.

Look for features like secure data access by trusted network devices only.

Vimachem's Digital Electronic Logbooks Solution

Built for digital transformation & Pharma 4.0, the Vimachem eLogbook system expedites implementation time while reducing TCO by up to 80%.

Trusted by leading Pharma and Biotech companies globally, Vimachem’s Electronic Logbook solution helps pharma organizations to:

- Eliminate the use of paper.

- Reduce data entry times by 60%.

- Speed up release times by 45%.

- Increase Timely Follow-Up by 75%.

Vimachem’s eLogbook elevates processes with real-time data collection and approval functions, an intuitive web interface, and enhanced authentication and blockchain capabilities.