Level 3 Serialization & Aggregation Software

A Cutting-Edge Traceability Software Platform that allows integration to any Level 2 and corporate Level 4 System and compliance with global serialization requirements (DSCSA, Anvisa, EU FMD, etc.)

Product Tour

L3 Serialization Site Manager

The Vimachem Level 3 Serialization Site Manager (SSM) is the world’s largest line and network agnostic serialization software solution.

It's part of Vimachem’s proven, performance-driven Digital Factory suite, a cutting-edge manufacturing intelligence software platform that fills the gap between corporate IT systems (MES, ERP, etc.) and the shop floor.

L3 Serialization Software

The Vimachem L3 Serialization Software is the only Level 3 in the market designed and developed in collaboration with Tracelink.

Its adaptive interface technology allows it to easily integrate (plug & produce) to any line or network system, offering a best-of-breed serialization solution and avoiding the issues (vendor lock-in, slow reaction times) that 1-vendor solutions suffer.

Features of L3 Serialization Software

The Vimachem Level 3 Serialization Software, is a GAMP 5, Category 4 Configured Product.

It consists of standardized modules and documentation packages that can be assembled and realigned to quickly accommodate changing demands.

- Master data module

- Rework module

- Label Design module

- Article Management module

- Manufacturing Analytics & OEE module

- Serialization Warehouse module

-

Packaging Scheduler module

powered by machine learning algorithms

Vimachem SSM Vendors

Benefits of L3 Serialization Software

Time Reduction

Reduced time to prepare and start production runs.

Error-Free Packaging

Elimination of incorrectly coded and packaged products as all errors are identified during testing and before actual production runs.

Continuous Production Flow

Minimized unscheduled line-stoppage.

Global Serialization Compliance

Compliance with global serialization requirements (DSCSA, Anvisa, EU FMD, etc.)

Increased production output & packaging OEE

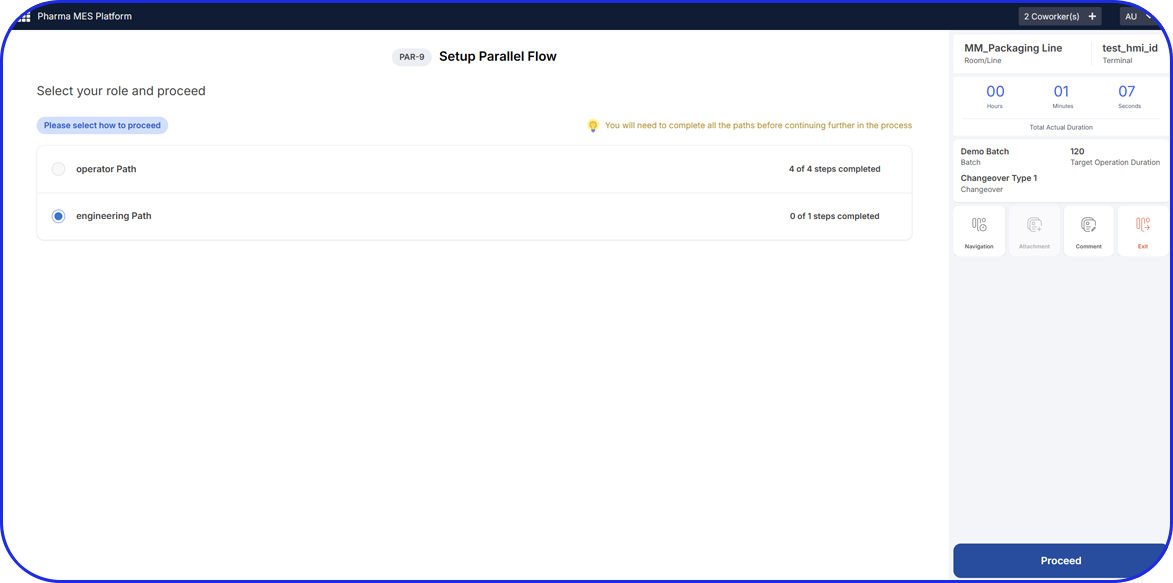

Assign and execute steps in parallel across users - streamlining team workflows.

Vimachem level 3 SSM results in significant operational efficiencies

The World's Largest Line and Network Agnostic Track & Trace Software

30 Countries

We are helping pharmaceutical manufacturers around the world.

900 Packaging Lines

We interface serialization and aggregation machines from 10+ serialization line vendors (Wipotec-OCS, Antares, Optel, Seavision, Seidenader, Mettler-Toledo / PCE, Scanware and more).

24/7 Global Support

Support teams located in 3 global locations (USA, Europe, Asia) able to offer timely consulting and support services.

Wipotec-OCS Level 2 Integration with Vimachem’s Level 3 SSM.

L3 Serialization Software Features with L4 & L5 Systems

Collaboration with Tracelink for Centralized Serialization Operations

Only level 3 in the market designed and developed in collaboration with Tracelink, the Vimachem L3 SSM allows operation of Tracelink from SSM, so all daily serialization operations (including commissioning and sending data to marketing authorization holders) can be performed from the Level 3 SSM user interface while Tracelink is working in the backend ( allowing internal teams to use only software system for daily serialization operations).

Automatic Data Transfer & Verification

Automatic data transfer (product master data, aggregation hierarchies, s/ns and more) and verification (according to Annex 11 Section 5) between Vimachem Level 3 SSM and Tracelink reduces manual input errors, setup time and line downtime.

L4 Interface based on EPCIS messages

Product Master Data Import & Update via Multiple Formats

Import and update product master data using SAP iDOC XML, SOAP or CSV files.

Flexible Production/Process Order Creation

Production / Process Order creation with or without Material Master Data using SAP iDOC XML or SOAP.

Integration Options for Tailored Solutions

Other custom SAP and Arvato integrations requested per customer.

L3 Serialization Software Features with L2 Systems

Elimination of Machine Downtime

Label/format design and management (retrieval of existing layouts from packaging lines and/or Nicelabel, Codesoft, version control, publish etc. ) eliminates machine down-time due to layout designing on the packaging shop-floor.

Complete Audit Log Retrieval & Merging for L1-3

Full audit log retrieval (including rejection reasons, camera grading, machine alarms etc.) and merge with L3 audit log for one combined L1-3 audit log.

Remote Serialization Machine Management

VNC / Remote Line HMI in the SSM allowing remote management of serialization machines from the Vimachem Level 3 SSM interface.

Configurable L2-3 interface

that includes:

• Pause and resume (also in different lines).

• Parallel production of different batches in serialization and aggregation machines.

• Other possible custom workflows requested by customers.

Real-Time & Offline Line Monitoring Capabilities

Real-time line monitoring (counts, rejections etc.) but also able to interface an L2 without live-connection ( depending on the L2).

Order Queuing for Efficient Packaging Operations

Order queuing allows scheduling of packaging orders in the Vimachem Level 3 SSM and automatic loading of orders on serialization machines (with only 1 order loaded at each machine per time) in a pre-defined order.

Validated Line Simulator for End-to-End Testing

Validated software line simulator allows end to end testing with supply chain partners without the need to utilize packaging machines.

Vimachem / Level 3 SSM and TraceLink Life Sciences Cloud.

L3 SERVICES

Level 3 Qualification Documentation and Validation Plan

Contact us

Ready to Augment your Shop Floor Operations?

Ready to Augment your Shop Floor Operations?

Get started with real-time manufacturing analytics today.