Digital Changeover Instructions & Analytics

AI-powered for digitizing, standardizing, and optimizing changeover – enabling right-first-time execution, real-time monitoring, and continuous improvement across pharma and biopharma manufacturing.

Accelerate Changeovers with Digital Precision

Standardize Your Changeovers

Manual changeover often varies across teams, introducing operational variability, inefficiencies and risk. Digital Changeover Instructions & Analytics enables standardization, and streamlines transitions with guided instructions and workflows – ensuring consistent, repeatable, performance across every shift, every time.

Optimize Changeover Times

Downtime during changeovers directly impacts production throughput and increases costs. The Digital Changeover Instructions & Analytics solution accelerates changeovers by automating processes, managing dependencies, and delivering analytics for continuous improvement - ensuring consistency across sites, maximizing operational efficiency.

Error-Proof Execution

Mistakes during changeovers can lead to quality issues, delays, and rework, adding significant cost to your organization. Digital Changeover Instructions & Analytics eliminates manual variability with real-time guidance, task validation, and outcome verification -ensuring right-first-time execution and consistent quality across every product and every batch.

See Vimachem's Digital Changeover Instructions & Analytics in Action

Built for Manufacturing, Operations, and Continuous Improvement Teams in Pharma & Biopharma

Pharma manufacturers face increasing demand for flexible, smaller batch production without sacrificing consistency or compliance. Digital Changeover Instructions & Analytics empowers your team to digitize and optimize every step of the changeover process.

Built to handle high product variability and tight production schedules, Vimachem’s Digital Changeover Instructions & Analytics streamlines transitions between runs while minimizing manual effort and errors by ensuring the team always has access to the most up-to-date guidelines for every operation using the latest changeover processes.

DCI&A provides you with the ability to:

- Digitally manage and track changeover activities in real time

- Ensure continued access to the most current SOPs and instructions

- Maintain high quality and performance even with workforce turnover or complex product lines

- Reduce setup time and boost equipment utilization

Six Reasons to Digitize your Changeover Module

Gain Real-Time

Visibility

Track step times across the process and gain timely insights for faster, informed decisions.

Configurable Reporting & Dashboards

Visualize performance, collect data, and strengthen SMED with actionable insights.

Digitize Changeover Matrix

with AI

Convert PDFs to structured digital instructions in minutes using AI-powered tools.

Enrich Changeover Processes with Media

Add images and videos to improve operator understanding and execution speed.

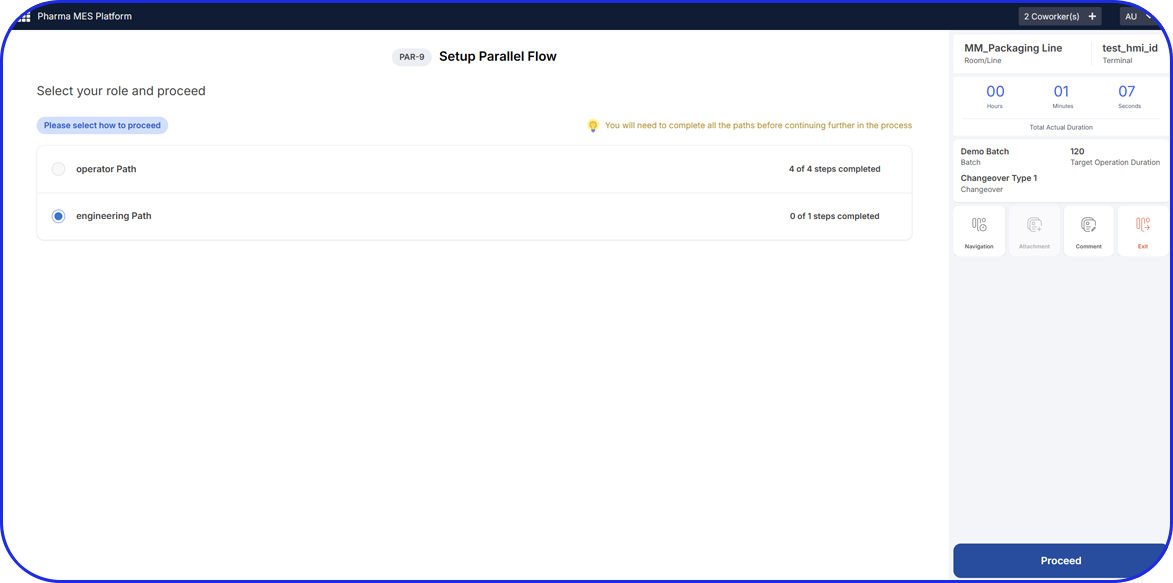

Enhance Collaboration

Assign and execute steps in parallel across users - streamlining team workflows.

Equipment Monitoring

Evaluate changeover performance for equipment and identify assets based on compliance and efficiency.

Vimachem’s Digital Changeover Instructions & Analytics has brought repeatability and speed to our changeovers. We’ve cut downtime significantly while empowering our operators with clear, guided instructions.

VP of Manufacturing Operations, Global Pharma CDMO

Scalable Expansion with Modular Add-Ons

Maximize operational efficiency and compliance by extending Digital Changeover Instructions & Analytics with additional Vimachem modules. Integrate Electronic Batch Records (eBR) to streamline execution and documentation, and Manufacturing Analytics & OEE to gain real-time performance insights across production operations and drive continuous improvement.

Contact us

Ready to Augment your Shop Floor Operations?

Ready to Augment your Shop Floor Operations?

Get started with real-time manufacturing analytics today.