Pharma MES Platform

Pharma MES Platform

Intelligent MES for Pharmaceutical and Biopharmaceutical manufacturing.

THE VIMACHEM DIFFERENCE

// Scale faster with greater flexibility

INTELLIGENT AND COMPLIANT

// Fully validated, cGMP and 21 CFR Part 11 compliant

Our intelligent MES IIoT-driven platform is designed specifically for life sciences. Vimachem understands how operators interact with their equipment and environment so that real-time contextualized feedback can be given on the floor as needed. Go from planning to product delivery seamlessly, while maintaining compliance so that critical drugs get to market safer and faster.

UNLOCK THE VALUE OF YOUR DATA

// The right data, at the right time, to the right team

CONNECT AND UNIFY ALL YOUR FACTORY

// Meaningful and actionable information

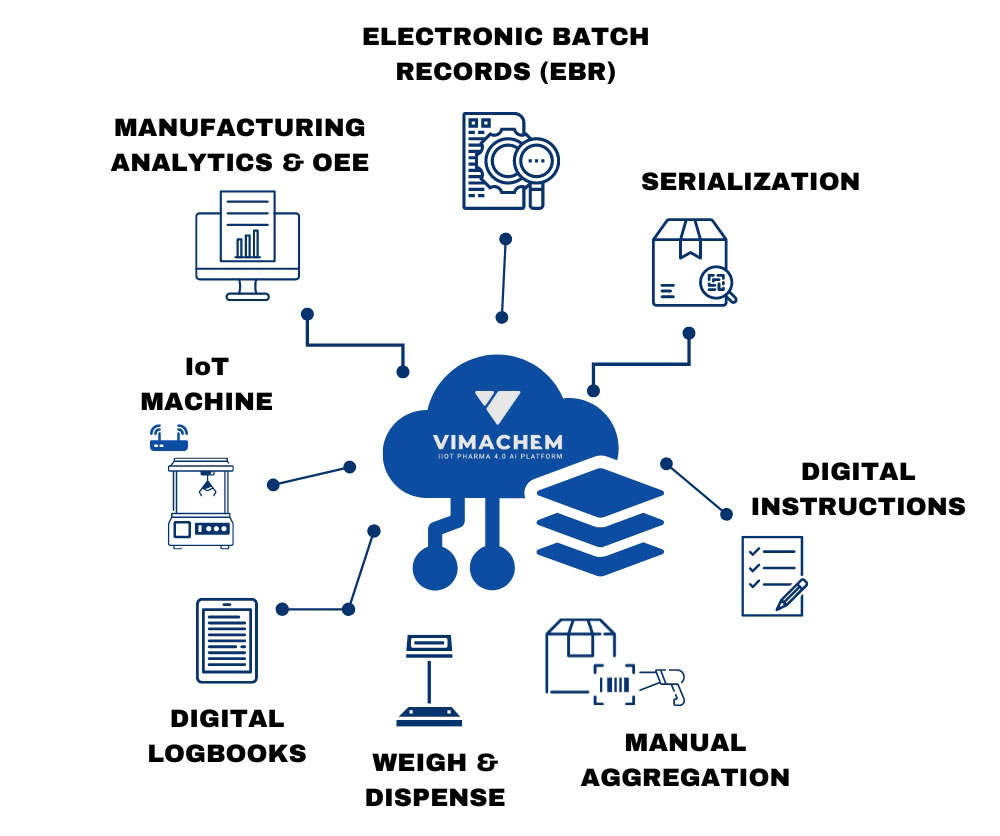

Vimachem Optimz Pharma MES Platform

// From connecting devices to optimizing manufacturing and quality

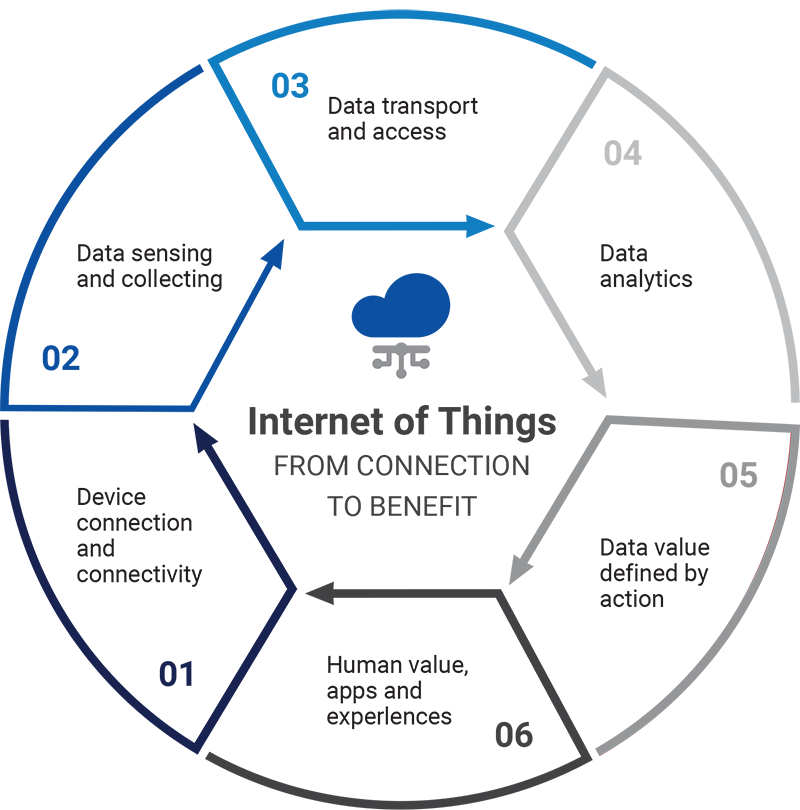

AI Meets the Industrial Internet of Things (IIoT)

Vimachem brings the next-gen of Industrial AI apps that interpret and predict, using deep analytics and machine learning techniques, to transform industrial data into business outcomes to enable improved product quality, increased productivity and ultimately better patient outcomes, faster than ever before.

Optimz is used by pharmaceutical and biotech manufacturers to deploy pre-built applications that improve manufacturing efficiency, quality and ensure compliance. Offered as a service, it lets you combine plug-and-play connectivity with on-premises or cloud data management and processing to support real-time applications for smart manufacturing and remote operations.

DEVICE CONNECTION

IoT devices

IoT connectivity

Embedded intelligence

DATA SENSING

Capture data

Sensors and tags

Storage

COMMUNICATION

Focus on access

Networks, cloud, edge

Data transport

DATA ANALYTICS

Big data analysis

AI and cognitive

Analysis at the edge

DATA VALUE

Analysis to action

APIs and processes

Actionable intelligence

BUSINESS VALUE

Increased Productivity

Increase Product Quality

Reduced Costs

Our Platform’s modules can be deployed as standalone and feature end-to-end functionality across manufacturing and quality operations

Our four modules can be deployed as standalone and feature end-to-end functionality across manufacturing and quality operations

This allows you to select the software components you need and focus on digitalizing your production step by step.

// GxP Compliance

Discover how Vimachem’s Pharma MES Platform enables a new era of autonomy and the Self-Optimizing Pharmaceutical Plant

- Accelerate your digitization journey to achieve new levels of operational excellence and reduce paperwork.

- Improve safety and sustainability by optimizing production scheduling and assets / machines reliability.

- Achieve the operational agility and flexibility needed to respond quickly to changing market demands.

- Empower the new era of knowledge workers, allowing them to focus on the highest-value-add activities.

- And ultimately produce more with less!

Pharma MES Platform MODULES

ELECTRONIC BATCH RECORDS (EBR)

A cloud-based digital solution that will help you streamline your production, reduce quality defects and ensure compliance & auditability. Built exclusively for Pharma & Biopharma manufacturers, the software enables faster and more robust implementations.

WEIGH & DISPENSE MODULE (WDM)

A digital solution that enables you to streamline your dispensing activities and ensure compliance & efficiency. Built for Pharma & Biopharma manufacturers, the software is pre-validated & built on modern technology, enabling faster and more robust implementations.

MACHINE DATA CONNECTIVITY

Our Plug & Produce machine connectivity solution allows fast and easy integration of machines for instant actioning in a pharmaceutical production environment.

DIGITAL PHARMA FORMS & LOGBOOKS

Easily design any form and logbook, maximize data integrity, and enable real-time monitoring of all production, cleaning, maintenance, breakdowns, or calibration events.

DIGITAL WORK INSTRUCTIONS & CHECKLISTS

Designed solely for Life Sciences, Digital Work Instructions and Checklists kickstart your digital transformation process and enable the right-first-time execution of daily operations.

MANUFACTURING ANALYTICS & OEE

Collect all site data, monitor OEE and machine utilization, streamline order flow and production execution and achieve operational efficiencies by reducing production costs and increasing throughput.

SERIALIZATION SITE MANAGER

A Cutting-edge Manufacturing Intelligence Software Platform that allows integration to any Level 2 and corporate Level 4 System, designed and developed in collaboration with Tracelink.

BIOPROCESS MONITORING SOFTWARE

Our Bioprocess Monitoring Software, makes use of artificial intelligence (AI) and industrial internet of things (IIoT) to monitor, analyze, and extrapolate value from manufacturing process data.

MANUAL AGGREGATION SOFTWARE

Manually aggregate up to three subsequent packaging levels and comply with worldwide pharmaceutical regulations in a perfect solution for manual, low-speed lines.

SELECTED VIMACHEM REFERENCES

READY TO AUGMENT YOUR SHOP FLOOR OPERATIONS?

READY TO AUGMENT YOUR SHOP FLOOR OPERATIONS?

Get started with real-time manufacturing analytics today.