Be Driven by Purpose

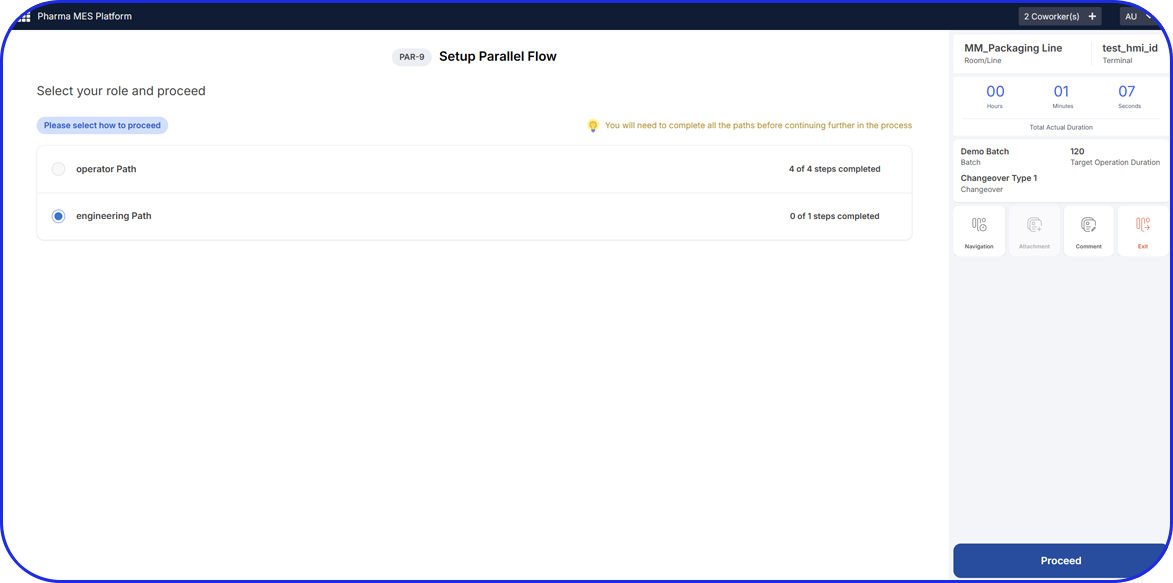

At Vimachem, we build technology that empowers the people who make the medicines the world relies on. Since 2015, we’ve been creating the industry’s only AI-enabled MES platform purpose-built for Life Sciences, enabling pharma and biotech manufacturers to deliver high-quality, life-saving medications.

If you want your work to make factories safer, processes smarter, and medicines more affordable, you’ll feel at home here. Join us and help shape the future of pharma manufacturing.

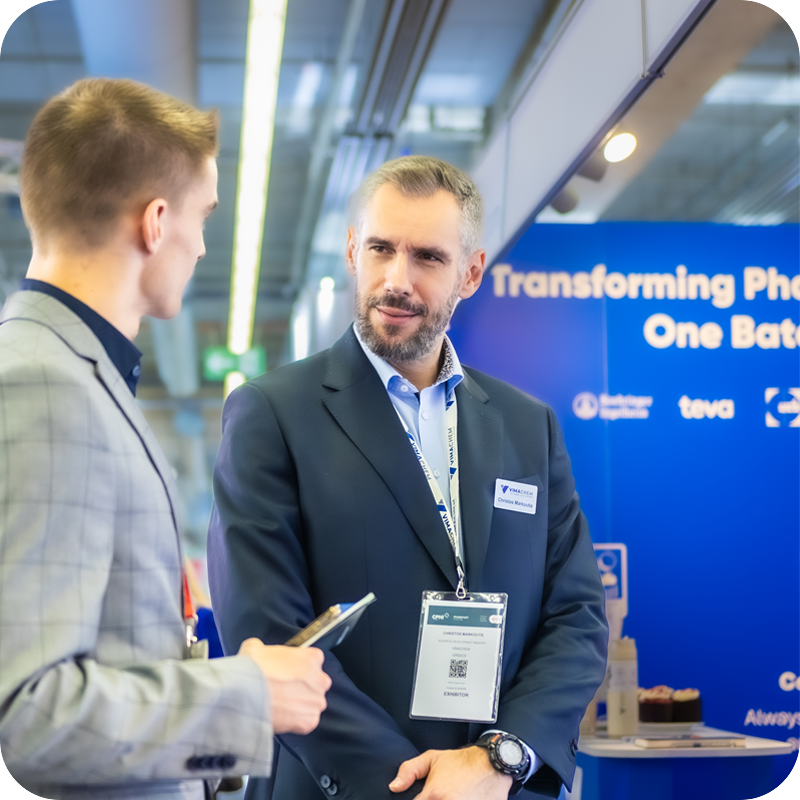

Life at Vimachem

Our Values

- Customer Excellence

- Ownership

- Learning

- Teams

- Speed

We are dedicated to our customers' success. By deeply understanding their business, we transform their manufacturing operations and create measurable value.

Our work is mission-critical; we take full ownership of it, with attention to detail. We stand by our results, whether in success or setbacks, always driving value and facing challenges head-on.

We embrace a culture of continuous learning and innovation. By challenging the status quo and pushing the boundaries of AI, automation, and Pharma 4.0 technologies, we ensure our solutions remain cutting-edge and impactful.

We hire, develop, and invest in the best talent. Our leaders are hands-on problem-solvers who work cross-functionally, lead by example, and inspire action beyond the comfort zone. By fostering an environment of trust, accountability, and high performance, our leaders empower their teams to achieve organizational and personal growth.

We believe speed drives progress. We take initiative, execute with precision, and continuously iterate to improve. Progress comes with action - we take calculated risks, learn, adapt, and move forward.

More Than a Job - a Rewarding Experience

We recognize that our rapid growth is driven by the hard work of our people. That’s why we want our people to have a share in the company’s success.

Fully remote

hybrid or onsite work options

Equity

stock option plan

Bonus

scheme

Health/Life insurance

& Dental Services Coverage

Monthly

Lunch Allowance

Continuous

Learning & Development

Onboarding

Support

Regular

Team & Company Events

Free office snacks

daily

Free lunches

whenever new team members join

Life at Vimachem

Meet the Tech Team

Principal Software Engineer

- Product & Engineering / Remote or Hybrid (GR)

As a Principal Software Engineer, you will work across Agile/Scrum squads, collaborating closely with senior engineering leadership, Product, QA, and DevOps to design, build, and evolve the Vimachem Pharma 4.0 Platform. A highly visible role with significant influence.

Senior Frontend Software Engineer

- Product & Engineering / Remote (GR)

Lead MES Consultant

- Customer Success / Remote (EU)

As a Lead MES Consultant, you will leverage your deep understanding of both Vimachem solutions and the Life Sciences manufacturing industry to drive operational and delivery excellence across pharmaceutical and biopharmaceutical manufacturing organizations.

Lead DevOps & Infrastructure Engineer

- Product & Engineering / Remote or Hybrid (GR)

As a Lead DevOps & Infrastructure Engineer, you won’t just maintain systems – you’ll architect and evolve Vimachem’s global infrastructure, guiding our DevOps strategy and define standards for automation, security, and scalability while remaining technically hands-on.

Recruitment process

Our recruitment process is challenging, so when you join, you feel equally amazing with us!

Apply

Tell us about yourself - upload your CV and a few words on why you’re excited to join Vimachem.

Interview

We'll dive deeper into your experience, approach to problem-solving, and culture fit.

Phone Screen

A call to get to know each other better, anderstand your goals, and answer your initial questions.

Onsite visit

Come see where the magic happens. You'll get a feel for our space, meet more team members, and see if we click.

Assignment

Show us your skills with a role-specific challenge designed to reflect real tasks you'd work on.

Get hired!

Congrats! If it's a match, we'll send you an offer and get ready to welcome you on board.

Meet the Team

Hear from our people.

“What I love about Vimachem is the mix of collaboration and innovation. You’re surrounded by people who push boundaries but also support each other. We move fast, learn constantly, and solve real Pharma manufacturing problems that matter.”

Russell Coelho

Solution Consulting Manager

“Working at Vimachem is amazing! The culture is open, and performance-driven, with low hierarchies and colleagues who are always supportive and fun to work with. The company is growing fast, which means you constantly learn, take on new challenges, and see the real impact of your work. I especially enjoy collaborating with new clients and projects, which keeps every day exciting and full of opportunities to grow.”

Saud Khan, Sr.

IT Serialization Consultant

“What I love about Vimachem is that you’re constantly encouraged to experiment, learn, and stretch yourself. It’s a place where you can do a lot, grow a lot, and truly feel that your work contributes to something bigger. For me, partnering with our department leaders and founders to shape how we hire, support our people, and strengthen our culture is one of the most challenging and rewarding parts of my journey here.”

Evi Angeli

“Joining Vimachem was an easy decision for me – it’s a place where technology meets purpose. We’re not just building software; we’re shaping the future of digital pharma manufacturing. What I enjoy most is the culture of collaboration and innovation that turns ideas into real products, improving how factories operate. It’s inspiring to work alongside passionate people who truly care about making an impact.”

Kyriakos Paraschopoulos

“What stands out at Vimachem isn’t just the product or the mission, it’s the people! We’re solving real challenges in how medicine is made and delivered, and the work reflects the importance of that. The pace is fast and the standards are high, yet the environment is genuinely supportive and collaboration feels natural. Trust and ownership are part of how we work and this is the kind of environment where you do some of your best work.”

Emma Hanley

Senior Product Marketing Manager

Meet the Team

Hear from our people.

“What I love about Vimachem is the mix of collaboration and innovation. You’re surrounded by people who push boundaries but also support each other. We move fast, learn constantly, and solve real Pharma manufacturing problems that matter.”

Russell Coelho

Solution Consulting Manager

“Working at Vimachem is amazing! The culture is open, and performance-driven, with low hierarchies and colleagues who are always supportive and fun to work with. The company is growing fast, which means you constantly learn, take on new challenges, and see the real impact of your work. I especially enjoy collaborating with new clients and projects, which keeps every day exciting and full of opportunities to grow.”

Saud Khan, Sr.

IT Serialization Consultant

“What I love about Vimachem is that you’re constantly encouraged to experiment, learn, and stretch yourself. It’s a place where you can do a lot, grow a lot, and truly feel that your work contributes to something bigger. For me, partnering with our department leaders and founders to shape how we hire, support our people, and strengthen our culture is one of the most challenging and rewarding parts of my journey here.”

Evi Angeli

People & Culture Specialist

“Joining Vimachem was an easy decision for me – it’s a place where technology meets purpose. We’re not just building software; we’re shaping the future of digital pharma manufacturing. What I enjoy most is the culture of collaboration and innovation that turns ideas into real products, improving how factories operate. It’s inspiring to work alongside passionate people who truly care about making an impact.”

Kyriakos Paraschopoulos

Software Engineering Manager

“What stands out at Vimachem isn’t just the product or the mission, it’s the people! We’re solving real challenges in how medicine is made and delivered, and the work reflects the importance of that. The pace is fast and the standards are high, yet the environment is genuinely supportive and collaboration feels natural. Trust and ownership are part of how we work and this is the kind of environment where you do some of your best work.”

Emma Hanley

Senior Product Marketing Manager

Tech we Use