Machine

Real-Time Connectivity

An IIoT Edge application that enables you to connect any machine and unlock real-time production visibility. Built for Pharma & Biopharma manufacturers, the software is designed for GxP environments and enables faster, scalable deployments.

Plug & measure any machine

Connect, collect and visualize real-time data from any machine or automation system on the pharmaceutical shop floor.

Transform machine data instantly

Clean, transform, encrypt and securely transmit machine data to on-premises or cloud systems for real-time machine monitoring.

Alerts and actioning

Alert the right person at the right time when action needs to be taken. Track incidents through a workflow with reassignment, resolution, and full audit logging.

See Vimachem’s Machine Connectivity Module in Action

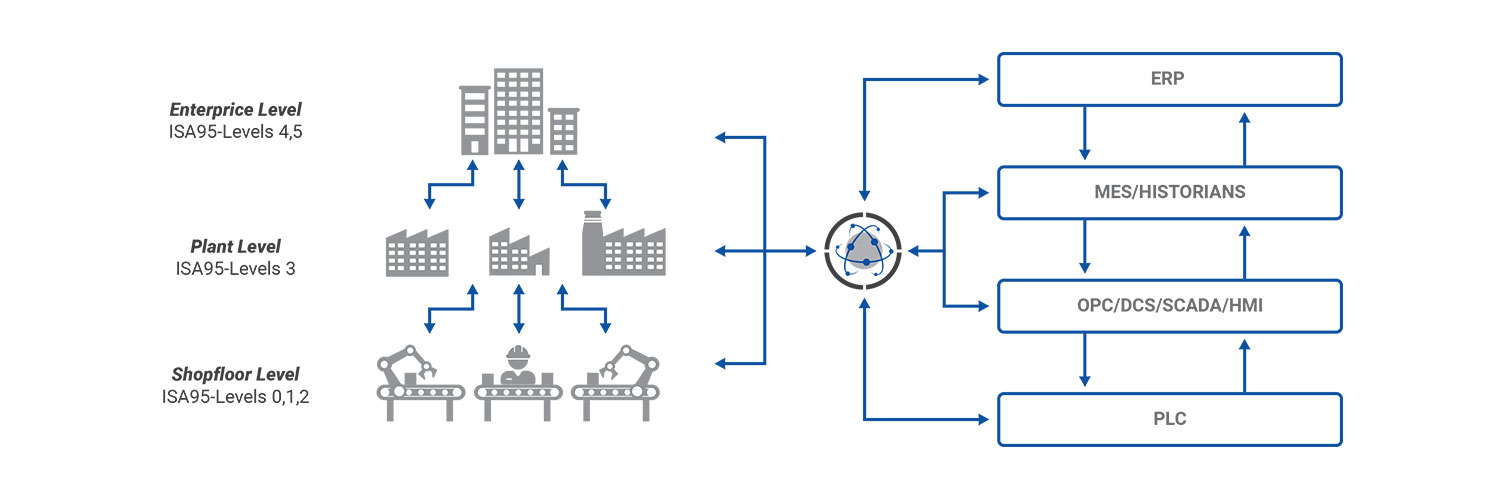

What is the machine data connectivity module?

The Machine Data Connectivity module is a plug & measure IIoT-driven solution that allows you to connect any machine across your pharmaceutical site / enterprise and use real-time machine data to instantly optimize production efficiency and product quality.

LACK OF REAL-TIME MACHINE DATA

In pharmaceutical manufacturing, the greatest impediment to process improvement is not always regulatory constraints.

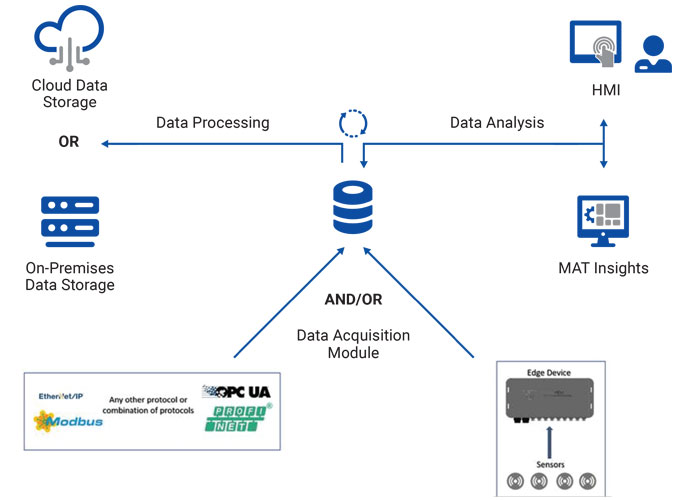

Vimachem Machine Data Connectivity IIoT-driven software provides a scalable solution for manufacturers that can be self-installed to easily collect data from any piece of equipment and send it to Cloud or to a local server, to enable actionable machine insights in a matter of minutes.

REAL-TIME

VISIBILITY

Benefits of the Machine Data Connectivity Module

Capture PLC and control data

Universal plug and measure data collection for PLC’s that support open protocols including MTConnect, OPC-UA, and Modbus.

Connect sensors quickly

To incorporate even the most difficult equipment, add external sensors or link older equipment with digital and analog IO that can be configured and operated centrally through a web interface.

Transform data instantly

To allow reliable reporting and analytics, our automated data transformation engine converts machine data into common data structures across all types of equipment. Custom Sensor Values, Machine Status, Modes, Alarms, Overrides, Load, Speeds, Feeds, Diagnostics, and other data objects are collected, transformed and stored ready to real-time analytics.

Deploy with flexibility

Easily deploy Vimachem IIoT Edge devices connected directly to any modern machine control system via the ethernet port, or install our Edge software on your own VM or server.

Cloud integration (optional)

Data is encrypted and safely streamed to the Vimachem IIoT Cloud MES platform in real time via ethernet, wifi, or cellular connectivity.

- Support for OPC-UA, MQTT, DNP3, Modbus and IEC 60870 protocols.

- Support for many PLC brands, including Siemens, Allen-Bradley, Schneider Electric, GE, , Automation Direct, Bosch, Eaton, WAGO, Beckhoff, BACnet, Texas Instruments, Mitsubishi, Omron and more.

- Auto-Build functionality speeds up engineering efforts by reading the structure of a PLC program and automatically creating models templates and instances based on the PLC schema.

- Secure encrypted communications.

The Vimachem Difference

Fast to deploy

Plug and measure, easy to use and to scale.

Drive immediate value

Out-of-the box connectitivy to the pre-built Vimachem Pharma 4.0 Intelligence MES apps.

Connect to everything

Easily integrate all machines across your pharma production and packaging shopfloor.

Deep pharma expertise

Our deep understanding of the pharmaceutical manufacturing operations guarantees immediate ROI.

With deep expertise in machine and data protocols, Vimachem’s automation and software engineers have completed machine data connectivity projects in over 20 countries worldwide.

Our proven capabilities in machine data acquisition, combined with our deep technical knowledge of the pharmaceutical environment makes us the ideal partner for connecting machines across the pharmaceutical shop floor.

Ready to Augment your Shop Floor Operations?

Ready to Augment your Shop Floor Operations?

Get started with real-time manufacturing analytics today.