How ELPEN Increased OEE by 90% and achieved 299% ROI with Vimachem's Manufacturing Analytics & OEE solution

How ELPEN Increased OEE by 90% and achieved 299% ROI with Vimachem's Manufacturing Analytics & OEE solution

Labatec Achieves a 35% OEE Increase and achieved 324% ROI with Vimachem's Manufacturing Analytics and OEE Solution

Labatec Achieves a 35% OEE Increase and achieved 324% ROI with Vimachem's Manufacturing Analytics and OEE Solution

Trusted by 100+ Pharma & BioPharma Customers

Company Profile

"At the start, operators were hesitant about the system, but now they see how it helps them work more efficiently and reduce mistakes. The real-time insights have been a game-changer for us."

Iyad Shubaki, Operations Excellence Manager

Labatec Pharma is a Swiss-based pharmaceutical organization with a long-standing presence in Geneva. Labatec produces a broad portfolio of hospital-grade injectable medicines as well as oral solid dosage forms, spanning therapeutic areas such as anti-infectives, anaesthesia and ICU, oncology, women’s health, and musculo-skeletal conditions. Their portfolio includes both prescription (Rx) treatments and selected over-the-counter (OTC) products.

The company has expanded its operations by establishing key production facilities in Portugal and the UAE, reinforcing its commitment to operational excellence and efficiency. With a strong focus on continuous improvement, Labatec has embraced digital transformation to enhance manufacturing performance, streamline processes, and maintain compliance in the highly regulated pharmaceutical sector.

Production Overview

Labatec operates multiple manufacturing lines, including packaging and serialization and is committed to achieving higher efficiency, reducing downtime, and ensuring compliance with industry regulations. The site is equipped with a Marchesini blistering machine, a Marchesini–IMA cartoning machine, a Prisma checkweigher, and a Marchesini Neri printing and serialization unit.

The Challenge

Prior to implementing Vimachem’s Manufacturing Analytics and OEE solution, Labatec faced several operational challenges:

- Lack of real-time visibility into production performance.

- Difficulty in tracking downtime and identifying root causes.

- Manual data collection processes prone to human error.

- Uncertainty in how to optimize changeovers and streamline production efficiency.

- Unstructured data collection as there was no clear starting point or benchmark, making it difficult to measure progress.

- Resistance from operators in adopting new technology.

- Difficulty in quantifying and prioritizing losses analysis.

- Difficulty to monitor the impact of improvement actions implemented.

Labatec needed a solution that would provide accurate, complete real-time data to support decision-making and drive continuous improvement.

Labatec adopted Vimachem’s Manufacturing Analytics and OEE solution to gain real-time insights into their production lines. The solution was implemented on one manufacturing line initially, with plans to expand based on the success of the deployment.

Key Features Utilized:

- Real-Time OEE Monitoring: Providing visibility into equipment performance, availability, quality and a series of related process KPIs.

- Automated Data Collection: Reducing manual effort and improving accuracy.

- Customizable Dashboards: Allowing operators and management to track KPIs effectively.

- Changeover Optimization: Enabling better scheduling and reduced downtime.

- Weekly Trend Reports: Highlighting key losses and helping prioritize improvements.

- Proactive Support & Collaboration: Vimachem’s team provided bi-weekly meetings to support Labatec, ensuring ongoing assistance and alignment with goals.

The Solution

Implementation Process

Once implementation began, an initial phase of testing and adaptation followed. The total duration of the project to reach a production-ready system was 8 weeks. After a few months of use, the system gained momentum, leading to a significant transformation and measurable improvements over the past year.

Key Steps in Implementation:

The full production-ready system was deployed in just 12 weeks, aligning with Fulton’s scale-up timeline and ensuring uninterrupted packaging operations.

1. Hardware Installation & Sensor Deployment:

2. Training & Adoption Strategy:

Understandably, some operators were initially unsure about the new system, as it represented a change in their daily routines. Labatec approached this thoughtfully—sharing live success stories, providing supportive training, and introducing improvements gradually. Over time, operators began to see the system not as oversight, but as a helpful tool that made their work easier by improving efficiency, reducing downtime, and streamlining changeovers.

3. Iterative Optimization (Hypercare):

Regular review meetings every two weeks to analyze performance data and identify opportunities for improvement.

4. Changeover Monitoring & Process Optimization:

Labatec identified inefficiencies and made process adjustments, such as monitoring decommissioning time, leading to improved efficiency and reduced errors.

"At the start, operators were hesitant about the system, but now they see how it helps them work more efficiently and reduce mistakes. The real-time insights have been a game-changer for us."

Iyad Shubaki, Operations Excellence Manager

The Results

Labatec has seen significant improvements since fully adopting Vimachem’s Manufacturing Analytics and OEE solution:

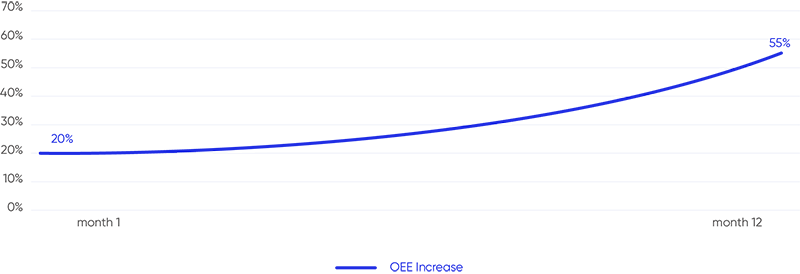

- OEE Improvement: Increased from 20% to 55% over 12 months, with a steady 3.3% increase per month.

- Equipment Uptime: Improved by 35%.

- Changeover Optimization: Reduced manual interventions and increased efficiency.

- Reduction in Downtime: Major stoppages were identified and two of the biggest issues were resolved, saving approximately 3 hours per cycle.

- Operator Engagement: A shift in mindset where operators now understand the system is designed to assist rather than monitor them.

- Enhanced Troubleshooting: Labatec used Vimachem’s system to track stoppages, identify issues, and implement immediate corrective actions, improving response time.

- Reduction in Human Error: The system provided a structured logbook to replace previously manual tracking methods, reducing mistakes.

Key Performance Indicators (KPIs)

- OEE Increase: +35% improvement

- Downtime Reduction: >10% decrease

- Changeover Optimization: Reduction in changeover time and elimination of inefficiencies.

Operational Gains

- Improved Data Visibility: Operators and management now have access to real-time performance data.

- Streamlined Changeover Process: Previously a manual and time-consuming task, now automated and optimized.

- Reduction in Operator Stress & Errors: The system helped pinpoint inefficiencies, reducing rework and manual errors.

- Continuous Improvement Culture: Regular KPI tracking and reporting have fostered a culture of ongoing enhancement.

- Scalability & Future Expansion: Labatec has begun exploring ways to expand the system across additional lines and manufacturing machines to maximize impact.

Key Benefits of Vimachem’s Manufacturing Analytics & OEE Module

- Ease of Implementation: Rapid deployment through a SaaS model.

- Seamless Integration: Compatible with existing ERP and manufacturing systems.

- Configurable Dashboards: Customizable reporting for operators and management.

- Compliance & Support: GxP-validated solution with robust audit logging.

- Scalability: Started with one line, with potential expansion across multiple production lines.

- Proactive Customer Support: Regular bi-weekly meetings with Vimachem, ensuring ongoing guidance and success.

Conclusion

Labatec’s adoption of Vimachem’s Manufacturing Analytics and OEE solution has driven significant operational improvements, from increased OEE and equipment uptime to reduced downtime and changeover inefficiencies. They have successfully fostered a data-driven, continuous improvement culture, with plans to further optimize its production lines and fully utilize the solution’s capabilities in the coming months.

Ready to Augment your Shop Floor Operations?

Ready to Augment your Shop Floor Operations?

Get started with real-time manufacturing analytics today.