Unlocking Pharmaceutical Excellence: The FDA Quality Maturity Model

The FDA Quality Maturity Model

Nefeli Stylla

QA & CSV Specialist

Are manual processes slowing down your compliance efforts? Is it time for the pharmaceutical industry to enhance operations and shift towards digital transformation?

FDA’s Quality Maturity Model (QMM) can serve as your roadmap to operational excellence.

In the rapidly evolving landscape of the pharmaceutical industry, where compliance and quality are paramount, organizations often find themselves buried under mountains of paperwork, struggling to keep pace with regulatory demands.

Imagine a world where compliance is not just a necessity, but a streamlined process that empowers your team to focus on innovation and patient care. Let’s talk about the FDA Quality Maturity Model-a transformative framework designed to elevate quality practices and when paired with digitization, redefine how you achieve compliance.

What is the FDA Quality Maturity Model?

The FDA Quality Maturity Model (QMM) is a structured approach that helps pharmaceutical companies assess and enhance their quality systems across various stages of maturity. It serves as a roadmap for organizations to navigate the complexities of regulatory compliance, ensuring that quality is ingrained in every face of operations.

The model outlines five distinct maturity levels, each representing a step towards operational excellence:

- Initial: Processes are ad-hoc and reactive. Compliance efforts are largely manual, relying heavily on paper documents, which often leads to errors and inefficiencies.

- Managed: Basic processes are established, but there’s still a significant reliance on manual systems. Companies begin to recognize the importance of standardization.

- Defined: Quality processes are documented and standardized across the organization. While paper trails are still prevalent, some digital tools may be introduced.

- Quantitatively Managed: Organizations leverage data analytics to monitor and control processes. Compliance has become more proactive, but significant paper-based systems still exist.

- Optimizing: At this stage, companies fully embrace digital solutions. Continuous improvement processes are in place, with data driven decision-making, and paper use is minimal.

Real-World Examples

Drawing from our experience as trusted advisors to the pharmaceutical industry, we’ve seen how mid-sized pharmaceutical companies struggle with compliance audits due to outdated paper-based systems. These manual processes can lead to delays in product releases, create an overwhelming volume of documentation to review, and make it difficult to extract actionable insights from daily operations. By assessing their maturity level, they realize they’re still in the “Initial” phase, increasing the risk of non-compliance. With a commitment to adopting the QMM, they set a clear path to digital transformation.

As they move to the “Defined” stage, they implement Electronic Logbooks (eLogbooks) that automate record-keeping and data collection. This not only reduces paperwork but also enhances traceability and accountability in their manufacturing and quality control processes. As a result, audit preparation time is reduced by 80%, Right first time documentation reaches an astonishing 100%, and batch release time is cut by 40%.

Another example is a large biopharmaceutical company that, after conducting a maturity assessment, recognized the value of advancing into the “Optimizing” phase. By integrating electronic batch records (eBR) and electronic logbooks (eLogbooks) into their operations, they improved their quality assurance processes which significantly reduced the time spent on compliance-related tasks and ultimately enabled faster, more reliable product releases.

The Digital Revolution in Pharma

The digitization of operations in the pharmaceutical industry is more than just a trend; it’s a necessity. The FDA Quality Maturity Model aligns perfectly with this shift, providing a framework that enables companies to integrate digital solutions seamlessly into their quality systems. By moving away from paper-based processes and embracing digital solutions, organizations can enhance compliance, reduce errors, and ultimately improve patient safety.

Imagine a scenario where compliance documentation is automatically generated, ensuring audit readiness, and data analytics provide actionable insights for decision-making.

This is not just a dream; it’s the future of the pharmaceutical industry, and it’s achievable with the right solutions.

Start your digital transformation.

Conclusion: Take the Next Step

As the pharmaceutical sector continues to evolve, companies must prioritize quality and compliance to stay competitive. The FDA Quality Maturity Model provides a clear path for enhancing quality systems, while digitization offers the tools to eliminate inefficiencies and reduce reliance on paper.

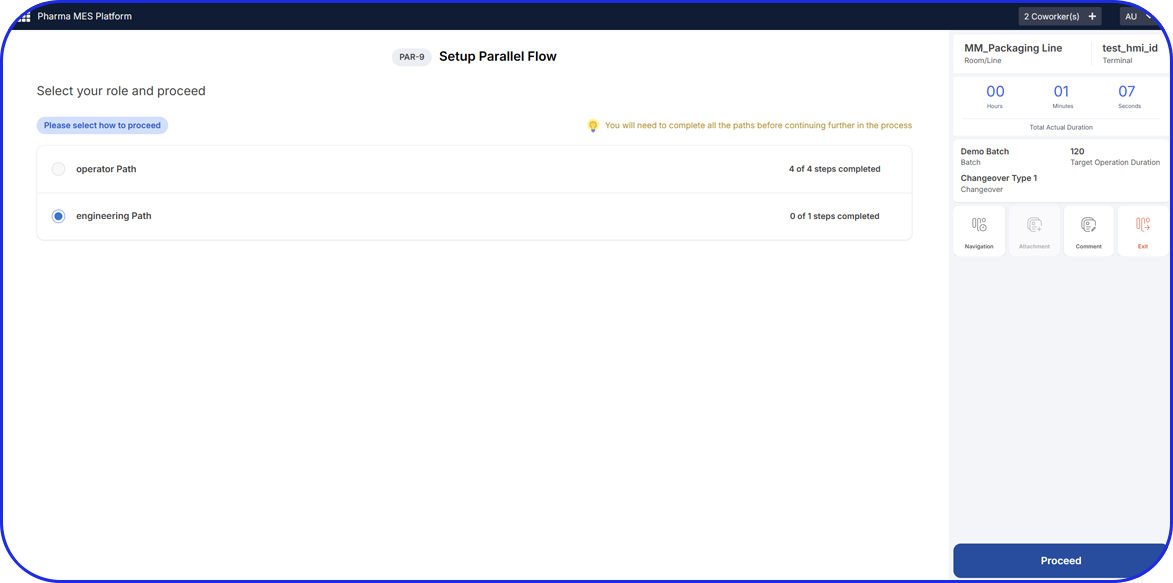

At Vimachem, we specialize in innovative software solutions that align with the FDA Quality Maturity Model. Our tools, including eBR, eLogbooks and Manufacturing Analytics & OEE are designed to streamline your compliance processes, reduce paperwork, and drive operational excellence.

Ready to move from manual systems to a fully optimized digital process? Embrace the future of pharmaceutical quality management – contact us today to learn how we can help you enhance your compliance while ensuring timely product releases and valuable insights from your data.

Ready to Augment your Shop Floor Operations?

Ready to Augment your Shop Floor Operations?

Vimachem Manufacturing Analytics - OEE

The Manufacturing Analytics – OEE module is an intelligent Pharma OEE Cloud solution that allows you to collect, store and visualize data across your site / enterprise and apply AI algorithms to optimize production efficiency and product quality.