How Citizen Developers and Low-Code Platforms Are Shaping The Future of Pharma Manufacturing

How Citizen Developers and Low-Code Platforms Are Shaping The Future of Pharma Manufacturing

Ioannis Danias

Continuous Improvement Specialist

Pharmaceutical manufacturing is on a transformative journey, and at its core are two dynamic forces: citizen developers and low-code software.

These elements are converging to redefine how pharmaceuticals are manufactured, monitored, and optimized. In this article, we will examine the ways citizen developers and low-code software are reshaping the future of pharmaceutical manufacturing.

The Current State of Pharma Manufacturing

Compliance and Digital Silos

The pharmaceutical manufacturing landscape combines process complexity and compliance regulations. The industry depends heavily on siloed software applications to manage daily operations, such as planning/scheduling, quality control, supply chain management, and quality management.

Software Issues

Traditional software applications are often costly, lack flexibility, and require skilled IT teams for development and maintenance, which can be challenging for pharma contract manufacturers where flexibility is required.

Bottlenecks and Challenges

Relying on standard software development can lead to bottlenecks, especially when rapid responses are crucial to address shifting market demands or accommodate changing regulatory requirements.

What is a Citizen Developer?

Citizen developers are a unique breed of professionals in the pharmaceutical industry. They may not have formal software development training, but their in-depth knowledge of the industry’s processes, standards, and quality requirements, combined with the ability to leverage low code development tools, enable them to create software solutions that address specific business needs within their area of expertise (a valuable asset in pharmaceutical manufacturing, where minor deviations from standards can have serious repercussions). Though the knowledge base of the individuals may vary, plant managers, supervisors, shop floor workers, and anyone else with a basic grasp of technology can become a citizen developer and continuously digitalize their business processes, ensuring improved product quality, increased efficiency and time to market.

The Role of Citizen Developers in Organizations

Bridging the Gap Between IT & Business Needs

Citizen developers connect IT and end-users by addressing practical needs directly, reducing IT bottlenecks in responding to business demands.

Driving Innovation from Within

Employees create solutions to optimize workflows and automate tasks. For instance, a production supervisor might design an app to monitor equipment performance.

Empowering Non-Technical Staff

Non-technical staff contribute to digital transformation, fostering innovation and reducing reliance on IT or external vendors.

Faster Solutions

Citizen developers shorten development cycles, rapidly addressing needs like compliance tracking or batch data capture.

Enhancing Collaboration

They improve cross-departmental collaboration by building tools that streamline data sharing between R&D, manufacturing, and QA teams.

The Collaborative Power of Citizen Developers and Traditional IT Departments

The future of pharmaceutical manufacturing hinges on close collaboration between citizen developers and professional IT teams, with process professionals bringing their domain knowledge to the table and citizen developers their expertise in IT scalability, and advanced integration.

Mentoring and Knowledge Sharing

IT departments have a crucial role in mentoring citizen developers, ensuring that the low-code development applications they create align with long-term organizational objectives. Knowledge sharing between these two groups fosters an environment of innovation and collaboration.

Holistic Solutions

The Role of Low-Code Platforms in Pharma

Low-code software platforms have emerged as a revolutionary force offering a user-friendly, visual development environment, allowing both professional and citizen developers to create applications with minimal traditional coding. Here are five compelling reasons why these solutions are a game-changer for pharmaceutical manufacturing:

Agility

Efficiency

Creating applications tailored to specific manufacturing processes increases operational efficiency and reduces the need for manual intervention, thus releasing human resources to other tasks.

Cost-Effectiveness

Quality Assurance

Compliance and Cybersecurity

Optimizing Pharmaceutical Processes with Low-Code Platforms

Low-code development platforms are revolutionizing pharmaceutical manufacturing by enabling businesses to address complex challenges with ease and efficiency. Below are key areas where low-code solutions are driving transformative change in the industry.

Customized Platform Workflows

Customized workflows combined with low-code development platforms create custom business applications that perfectly fit the plant’s workflows and processes. These applications can be used to improve efficiency, increase compliance, and streamline operations.

Quality Control Reinvented

Low-code platforms revolutionize quality control processes, making inspections more efficient, ensuring that pharmaceutical products meet quality standards, and instantly reporting deviations.

Real-Time Monitoring

Low-code platforms allow manufacturing processes to be monitored in real time, giving stakeholders unprecedented visibility into operations through digital transformation. This permits immediate intervention if a problem arises and promotes fast, well-informed decision-making.

Rapid Response to Change

The pharmaceutical manufacturing industry is no stranger to rapid regulatory changes, market dynamics, and consumer demands. When certain business processes are based on low-code platforms, business users have the agility to respond to these changes effectively without the need for app development.

Supply Chain Visibility

Pharmaceutical manufacturers can improve supply chain visibility and predict potential delays and unplanned deviations with low-code applications. This, in turn, limits the effects of disruptions and ensures a constant supply of materials.

Adaptability & Innovation in Pharmaceutical Manufacturing

Regarding the future of pharmaceutical manufacturing, one thing is clear: Adaptability is key! Citizen developers and low-code platforms will collaborate to drive innovation and efficiency in our highly regulated industry. Companies will invest in training, support, and resources that enable citizen developers to impact pharmaceutical manufacturing and fully realize their potential. By implementing a low-code platform, the pharma company gains a competitive advantage that allows it to upgrade traditional development methods and legacy systems.

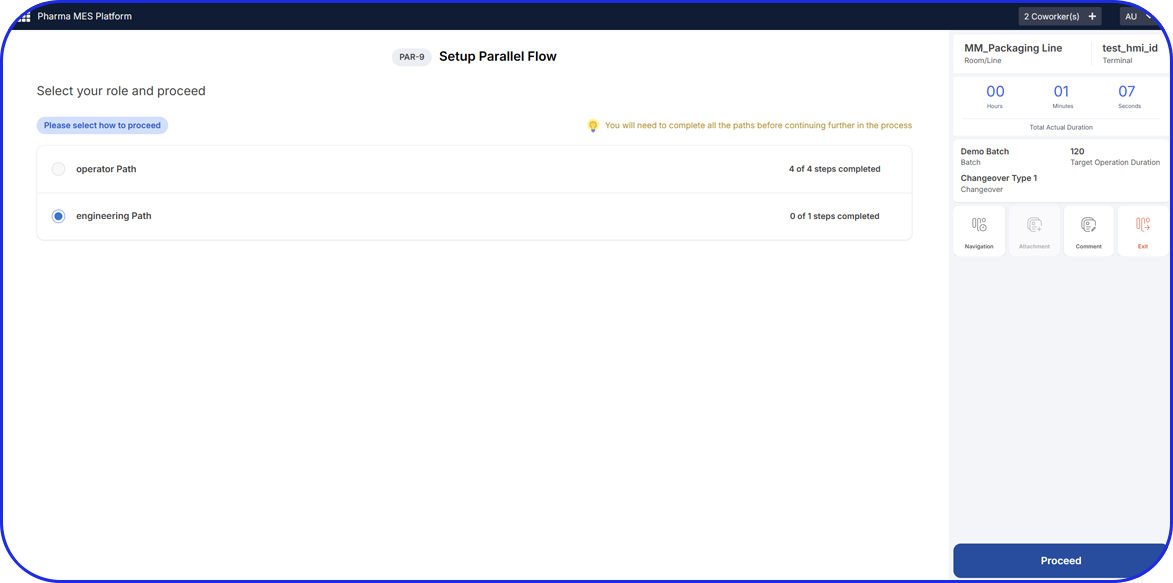

How Vimachem Supports Citizen Developers in Pharma Manufacturing

The dynamic duo of citizen developers and low-code platforms is reshaping the future of pharmaceutical manufacturing in a collaboration that provides a compelling solution to the issues of complexity, compliance , and the need for rapid adaptation. The benefits of flexibility, cost-effectiveness, and customized solutions are becoming transparent. By implementing automated procedures, low-code platforms accelerate the development process, yielding insightful data from business users and supporting data-driven decision-making for continuous improvements. With Vimachem’s no code modular Pharma MES Platform, pharma and biotech manufacturers can provide their citizen developers with modules related to real-time OEE Data, and Electronic Batch Records (EBR), Weigh and Dispense, and Work Instructions. The platform securely connects and unifies all plant data to deliver meaningful, actionable information to business users.

As the pharmaceutical manufacturing industry evolves, combining business users and low-code tools will no longer be an option. The combination of domain knowledge, technical expertise, and rapid development is the catalyst that will drive innovation and ensure pharmaceutical manufacturing success, achieving the vision of a more efficient reality while securing compliance and safety levels.

Ready to Augment your Shop Floor Operations?

Ready to Augment your Shop Floor Operations?

Vimachem Manufacturing Analytics - OEE

The Manufacturing Analytics – OEE module is an intelligent Pharma OEE Cloud solution that allows you to collect, store and visualize data across your site / enterprise and apply AI algorithms to optimize production efficiency and product quality.